Air compressors have become an essential power source in various industries and applications. From construction sites to manufacturing plants, these versatile machines play a crucial role in providing compressed air for a wide range of pneumatic tools. Understanding the power of air compressors and their ability to generate and maintain high levels of air pressure is key to harnessing their full potential.

An air compressor works by converting power, typically from an electric motor or a gasoline engine, into compressed air. This compressed air can then be stored in tanks or used directly to power pneumatic tools such as impact wrenches, nail guns, spray guns, and more. The ability to harness this powerful force has revolutionized the way we work with tools and machinery.

The concept of using compressed air as a power source dates back centuries, with early versions being used for mining operations and powering simple machinery. However, advancements in technology have led to the development of more efficient and reliable air compressors that are capable of delivering consistent levels of compressed air for extended periods.

The benefits of using an air compressor extend beyond just providing a reliable power source. Compressed air is clean, safe, and easy to store compared to other energy sources such as electricity or fuel. It allows for precise control over the amount of pressure delivered, making it ideal for applications that require accurate force or delicate handling.

In this section on understanding the power of air compressors, we will explore their various uses across different industries and highlight the advantages they offer over traditional power sources. We will delve into the mechanics behind how these machines generate compressed air and discuss key considerations when selecting an appropriate compressor for specific applications.

Whether you are a professional tradesperson looking to enhance your productivity or simply curious about how these machines work, this section will provide valuable insights into the world of air compressors and their significant impact on modern-day industries.

How Air Compressors Work and Their Key Components

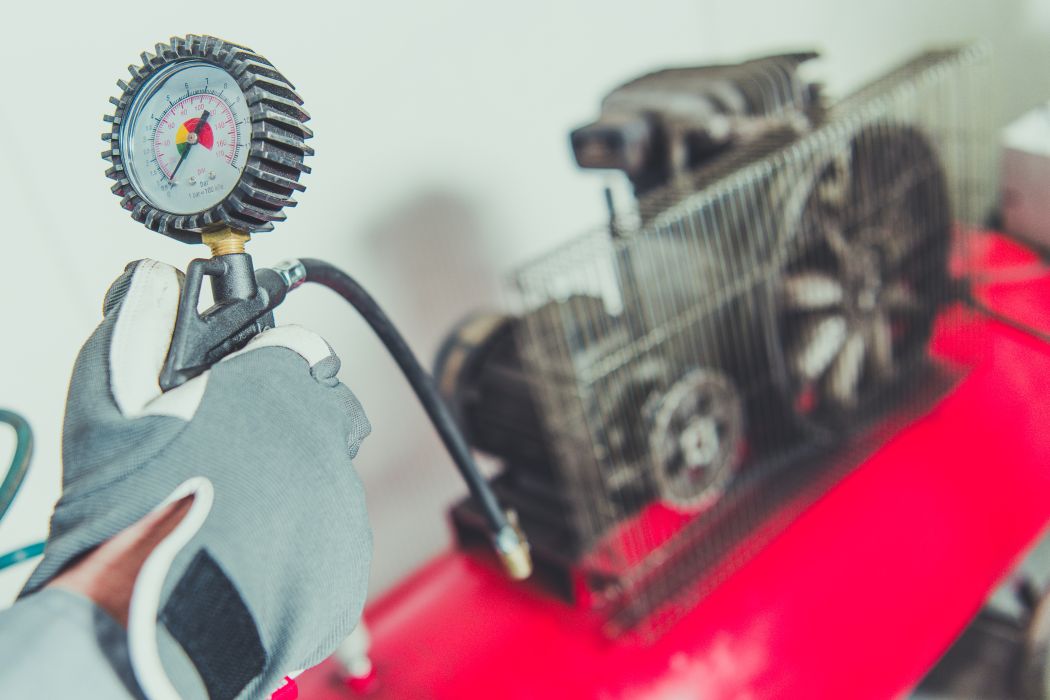

At the heart of an air compressor is the compressor pump, which is responsible for drawing in air and compressing it to a higher pressure. This pump consists of pistons or rotors that create the compression action. As the air is compressed, it becomes denser and its volume decreases.

To regulate the pressure produced by the compressor pump, a pressure switch is employed. This component monitors the air pressure inside the tank and automatically shuts off the compressor when it reaches a predetermined level. Conversely, when the pressure drops below a certain threshold, it activates the compressor to maintain consistent pressure.

The tank serves as a storage reservoir for compressed air. It allows for a steady supply of pressurized air even when demand fluctuates. The size of the tank determines how much compressed air can be stored at any given time.

Lastly, a regulator valve helps control and adjust the output pressure of compressed air from the tank. By turning this valve, users can set their desired working pressure according to specific requirements.

Understanding these key components of an air compressor provides valuable insights into how they function and how they can be optimized for different applications. Whether you’re in construction, automotive repair, or manufacturing industries, having this knowledge empowers you to make informed decisions regarding your choice and use of an industrial compressor for high pressure requirements.